Last couple of rounds have focused on the ship's compliment of various boats. This is a little trickier than it might be otherwise because you have to kind of puzzle piece things together between what's in the instructions and what you actually install and where...but more on that in a moment.

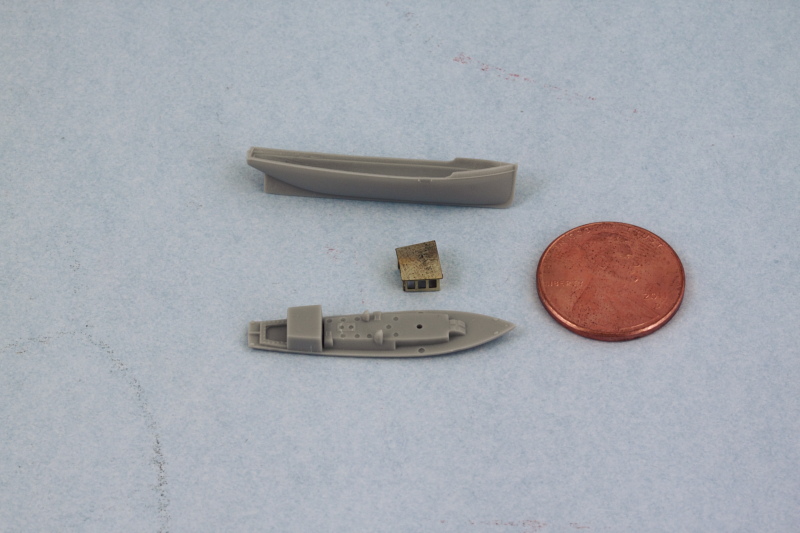

First order of business was improving some of the details on the three different steam-powered barge and pinnace craft. Trumpeter provides them as two part assemblies with the cabins molded solid (but hollow on the inside) as part of the upper deck portion. The Eduard set really improves the detail here by providing actual wheel-house/cabins with open windows, but that means surgically removing/cutting-down the molded on item so it can take its place.

After careful surgery and some sanding, you can get a pretty good result between the two. I also improved the detail level by drilling out the air funnels and the smokestacks on each of the three boats along with the main cabin port holes.

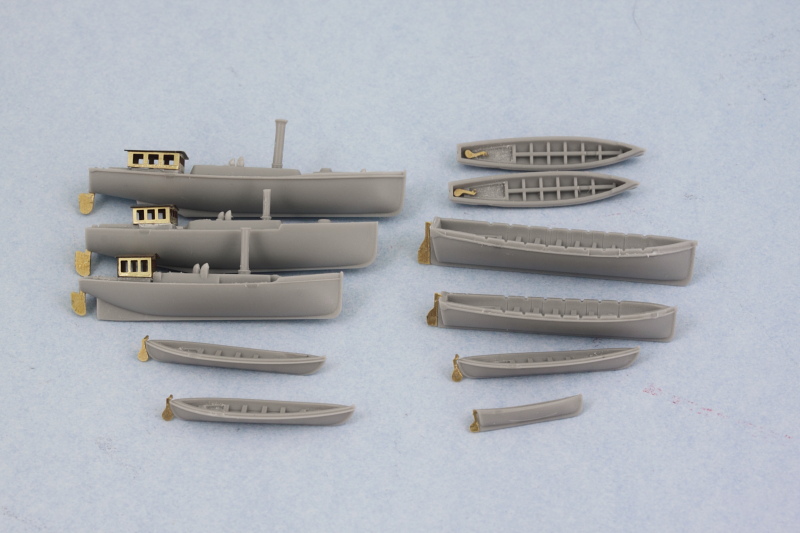

Now where life gets interesting is figuring out which of the kit-supplied oar-powered boats to use and where they will ultimately go. After studying the Kagero 3D reference photos, I figured out the following:

1) D43 are the 30 ft. gigs, and you need 2 of them, one on either side of the first funnel on the boat deck...but for them to fit, you need to not install the rudders and instead place them inside the boat itself as a stored item.

2) J1 isn't actually used anywhere even though the instructions have you assemble it...it's close in size to D43 but slightly longer...so it doesn't fit anywhere regardless.

3) D35 is the 16 ft. dinghy, you only need one of these and not the two that the instructions would have you build. The one you need will stack inside the port side suspended whaleboat.

4) J3 are the 32 ft. cutter life boats...you need 3 of these (one in the middle of the boat deck and 2 for the davits at the front of the boat deck). Unfortunately, the kit only provides one for the middle...so I've asked my good friend Steve Reid at Celtic Werks to cast some resin copies from the kit part to fill this gap, as a result they are 'MIA' from the group photo below until the casting is done.

5) D3 are the 27 ft. whaleboats, the instructions want you to build 5 but only 4 are needed (one in the middle of the boat deck, the other two hang from supports at the rear of the boat deck, one nests in the three-stack of boats on the port side). Ignore the weird directions that would have you stack a whaleboat and dinghy on top of the port side steam pinnace, that's a Trumpeter invention as far as I can tell.

While the instruction steps never show them actually installed, the 2 whaleboats and the dinghy that suspend from the rear portion of the boat deck do show up on the finishing guide as does the pair of 30 ft. gigs, so if you're paying attention you can catch that at least. All of the boats received their PE rudders in anticipation of some airbrush attention to lay down a base/primer coat of hull gray before they get further hand detailed.

Tomorrow will see the boats get further detailing so they can be ready for installation.