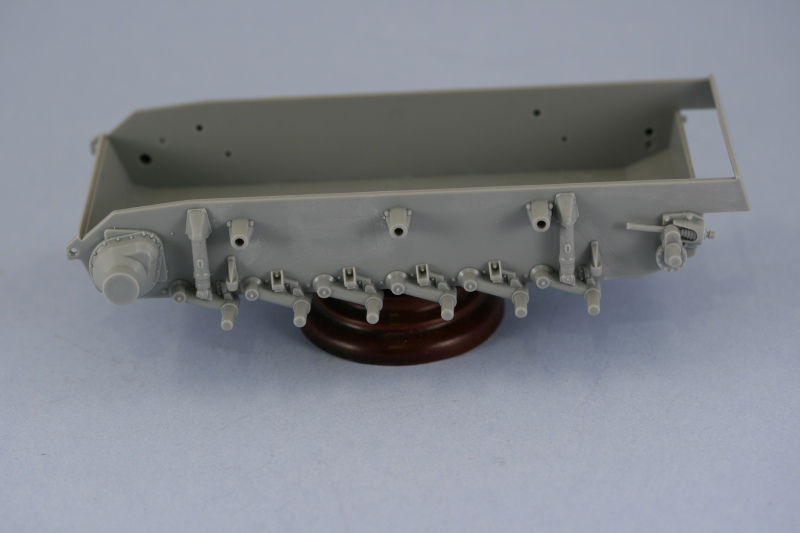

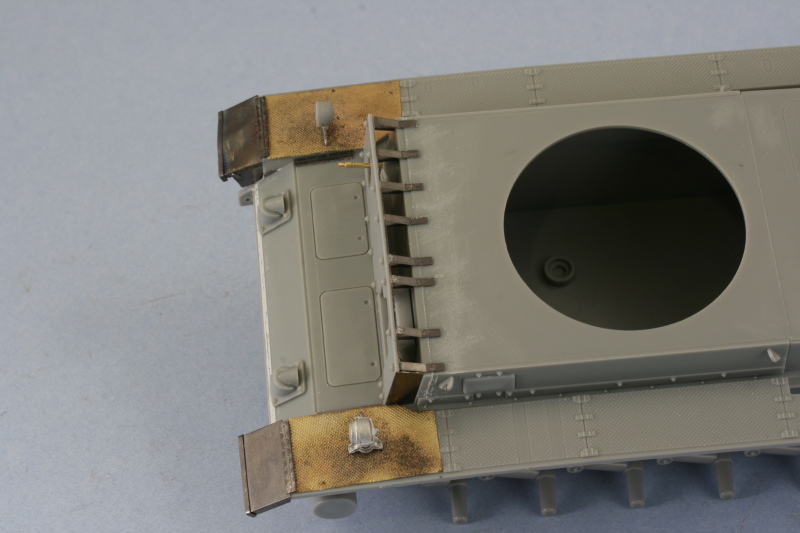

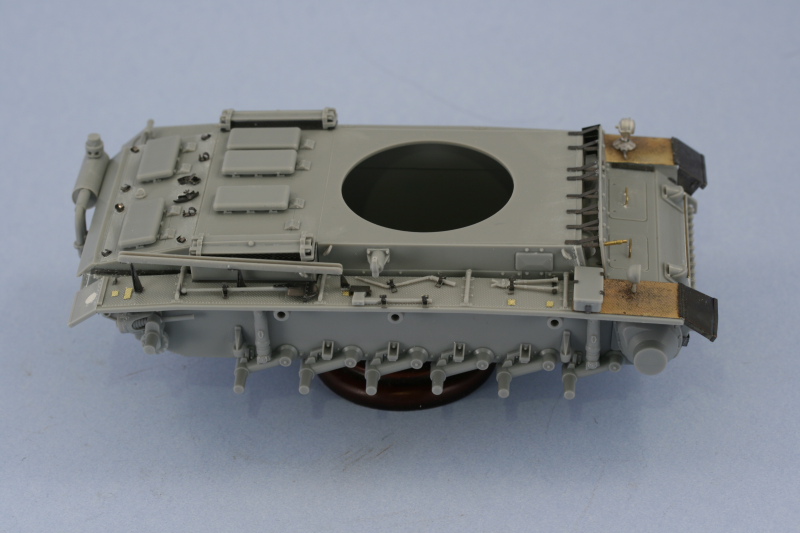

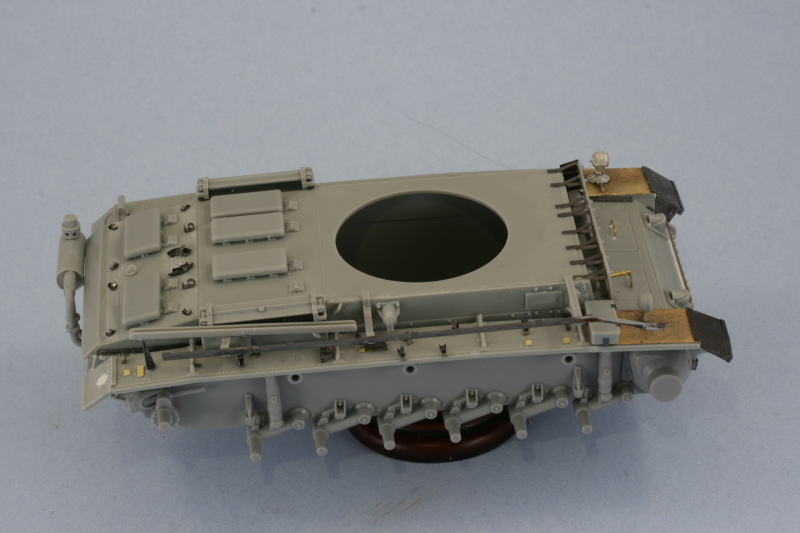

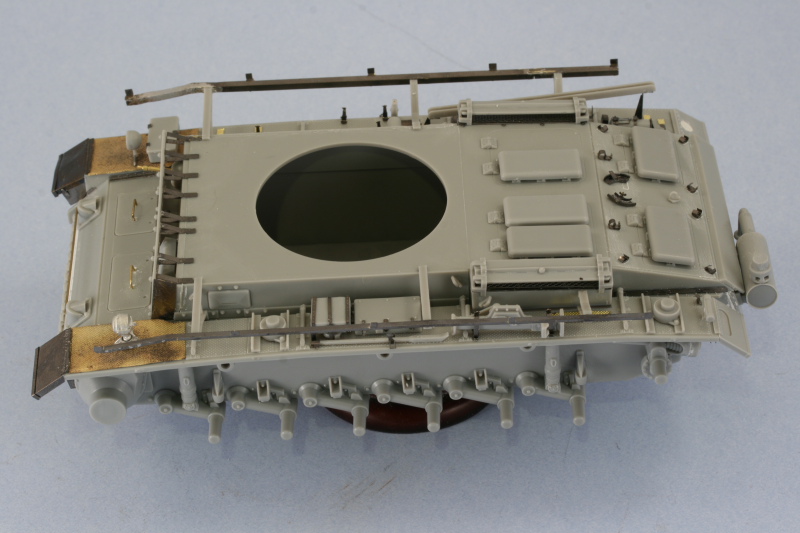

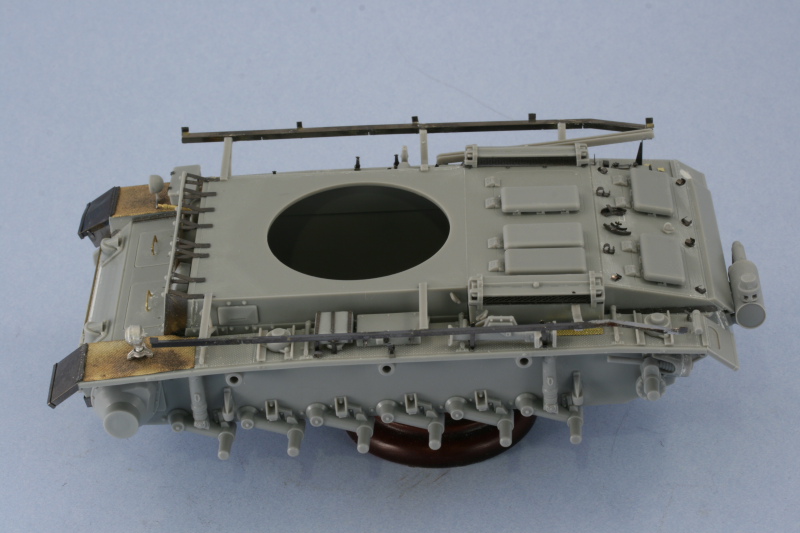

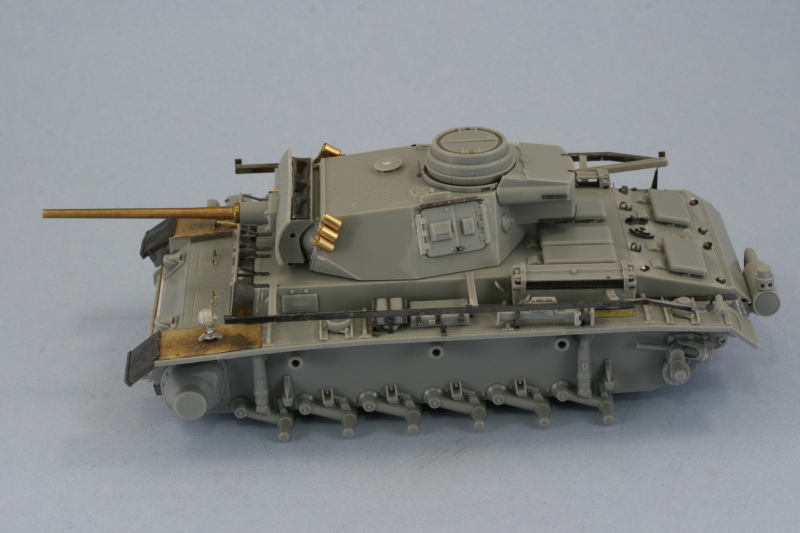

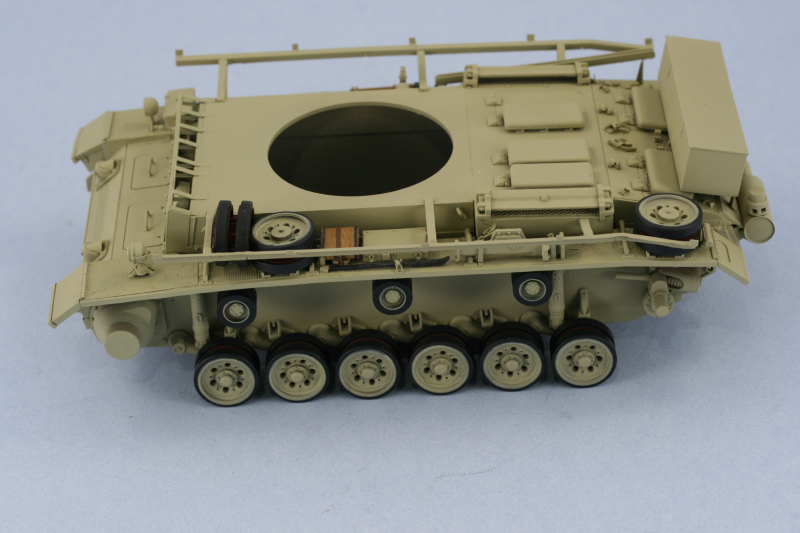

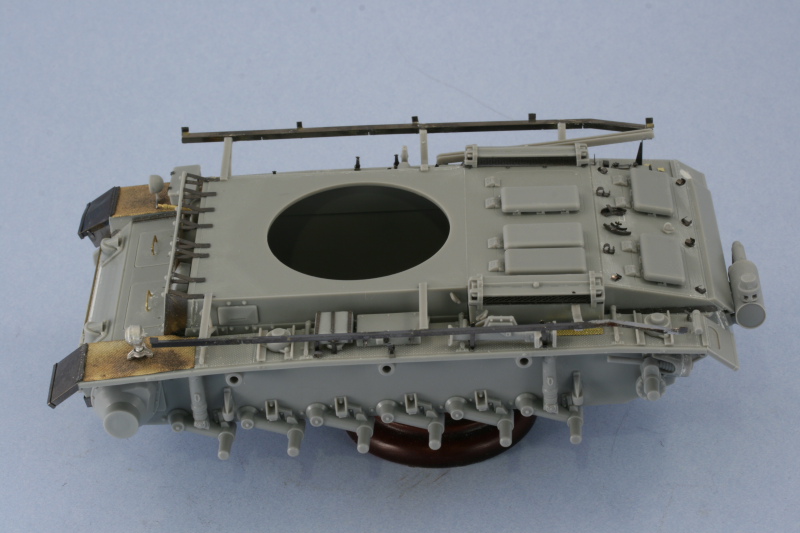

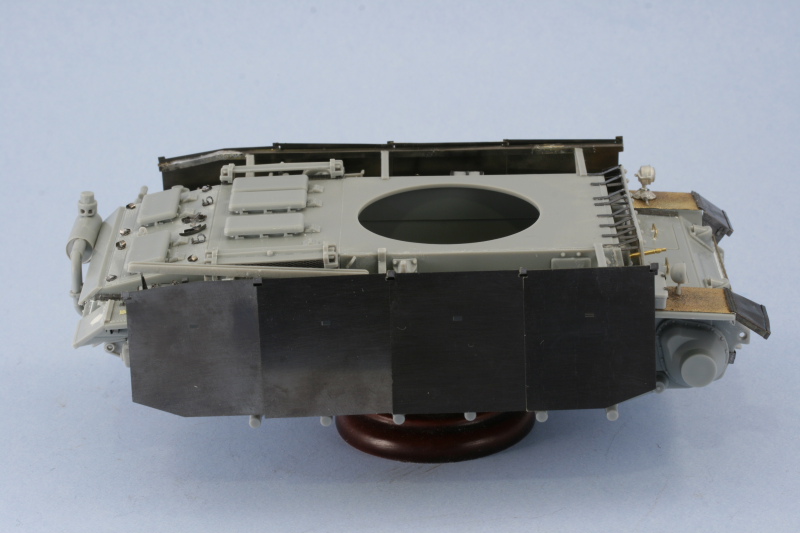

I was able to get in quite a bit of time today since I'd taken the day off for the Memorial Day weekend and the first order of business was to return to Step 12 and 13 and deal with the details on the left hand fender. At first I thought this side would go easier since there are fewer items to deal with but in the end it turned out to be just as much work as the other side. After much deliberation, I decided that the most important thing to install first were the schurzen rail supports in order to insure that they lined up correctly with both sides. To achieve this, I used a ruler and placed a marker dot with the tip of a black Sharpie in order to have a good location guide and then installed all three supports for the left side.

With those as my fence posts so to speak, it was now time to install the other various details and arrange them so they would all play nice with each other. First were the spare wheel holders and the front wheel holder needed to be moved about 1mm further toward the rear vs. the locator marks provided on the fender would suggest. This was necessary in order to allow sufficient clearance for the loose 3rd spare wheel that needs to be wedged between the wheel rack and the schurzen support according to the reference photos on #421. Next came the jack, I replaced it's molded on mounts with the Eduard items and secured it into place. The molded on bald strip where the fire extinguisher would normally go was filled in using another handy strip of the Aber fenders cut to size and glued in place with CA gel. Moving in on the middle portion, I removed all the molded on detail from the jack block and rebuilt it using the 7 PE parts provided in the Eduard set. I could only fit 1 S-hook underneath it instead of the 2 due to space limitations, so a small sacrifice was made in that department. The tool box received new patches and was glued in place and then the clamp and holder for the long pry bar were last. The pry bar wouldn't actually fit in the space available without interfering with the jack, so it was carefully trimmed down at the pointy end and then reshaped to allow it to fit in the triangular holder.

With all that set, I then installed the left side schurzen rail and let it all set up.

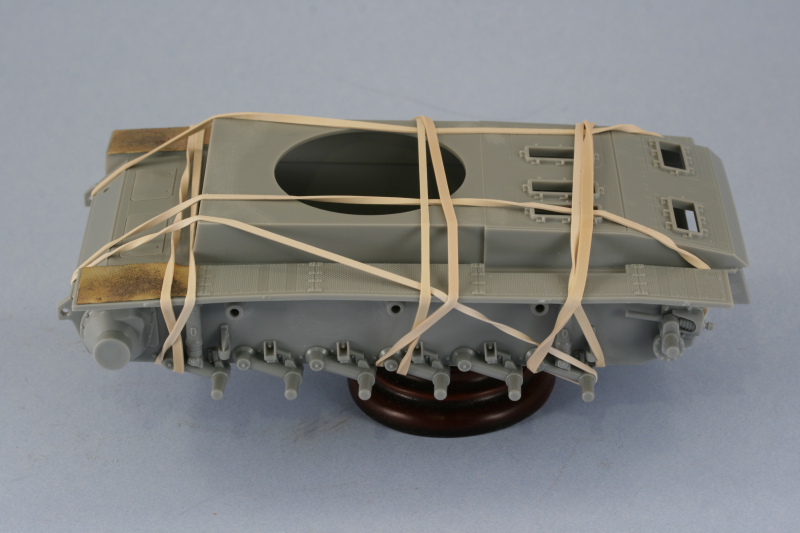

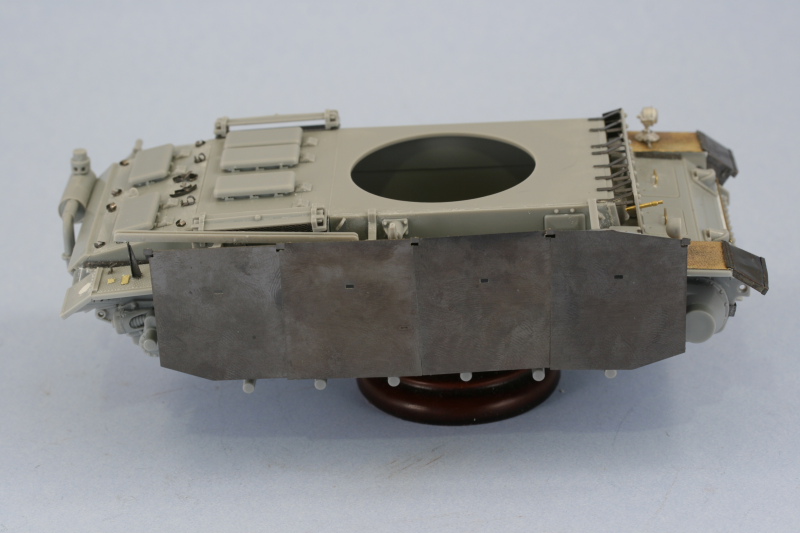

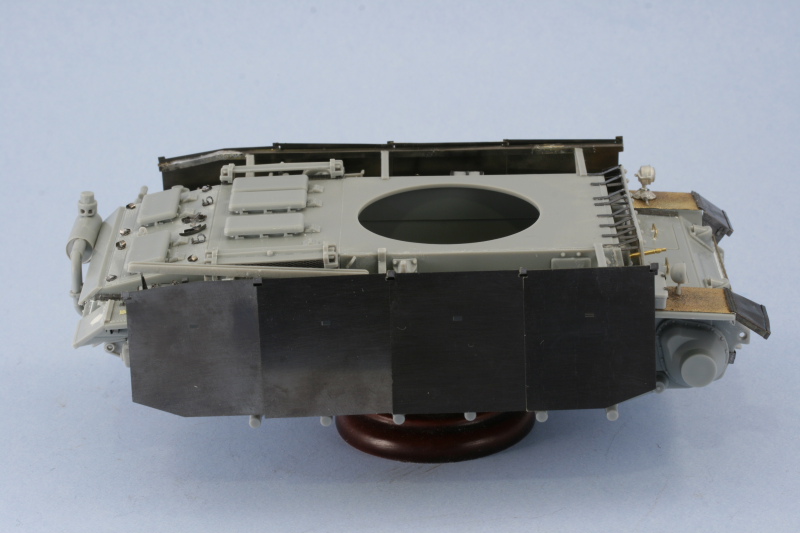

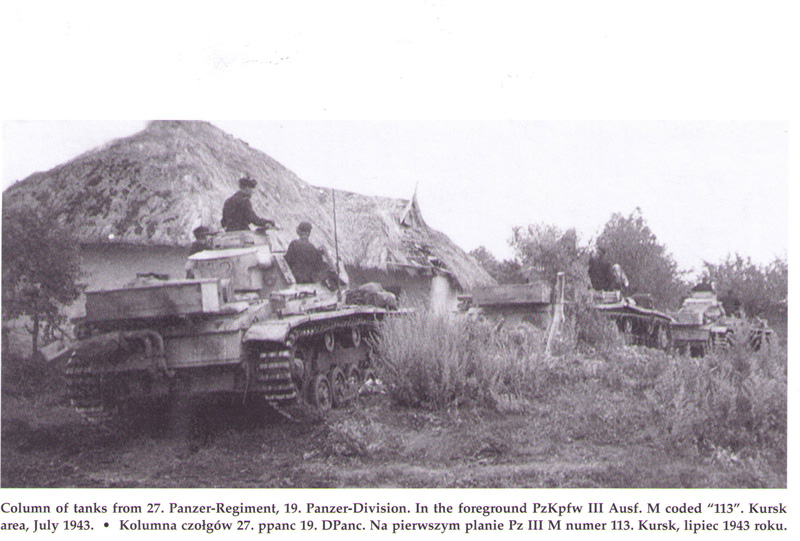

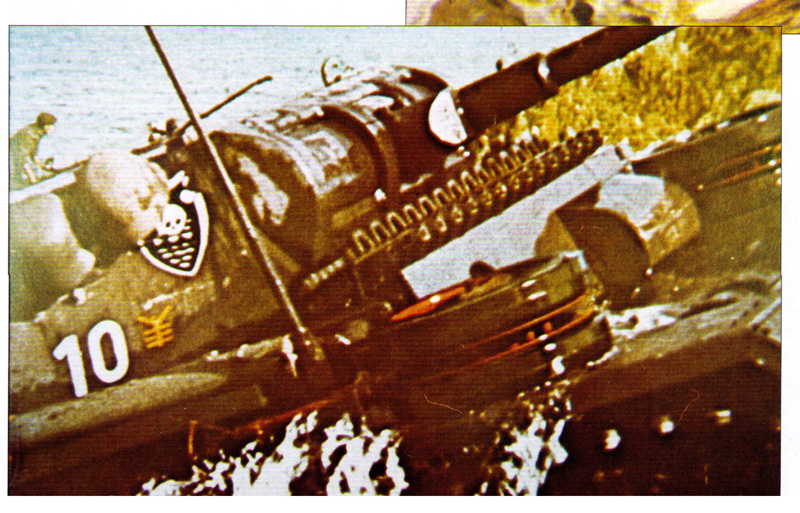

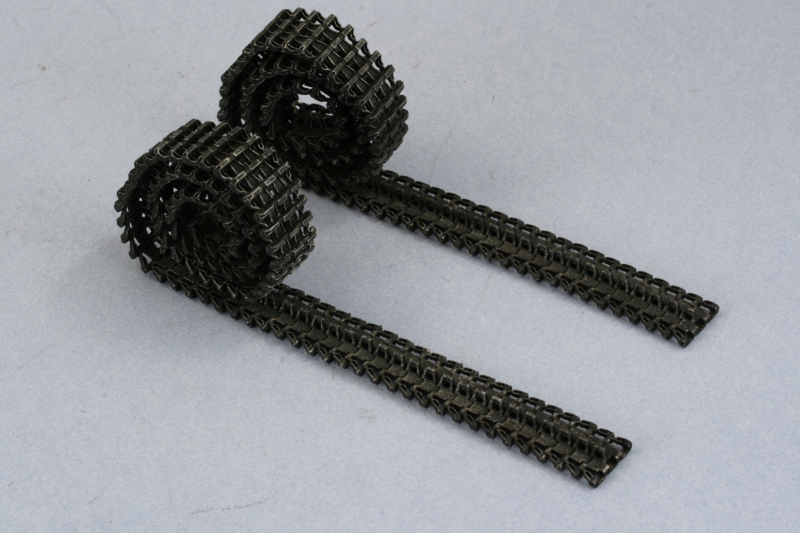

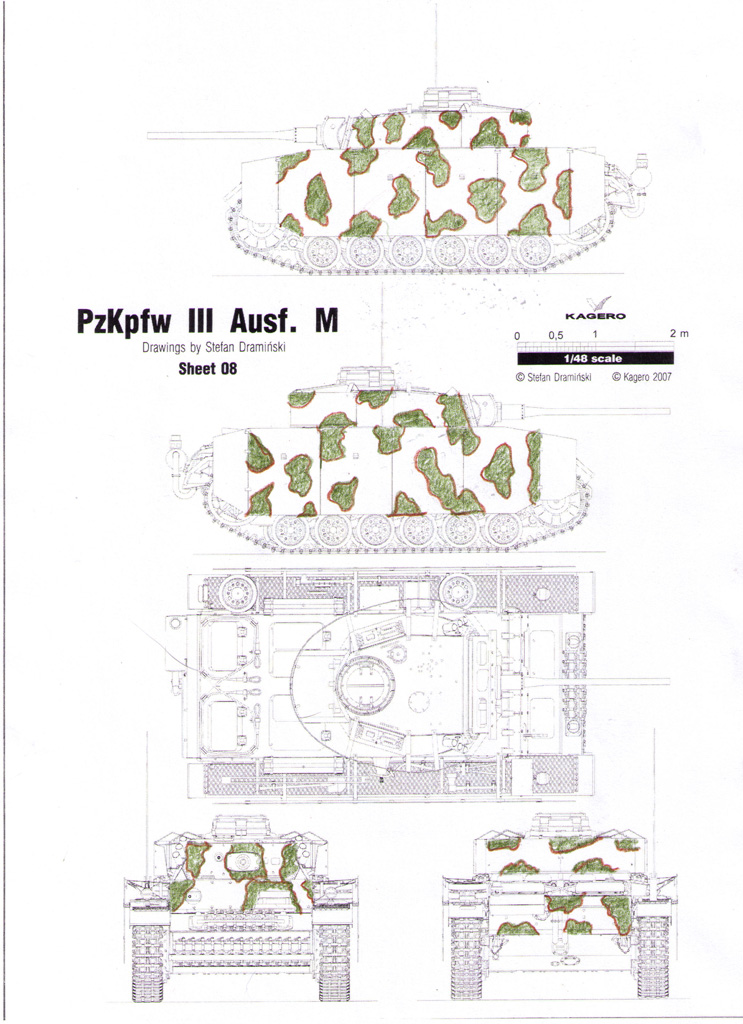

After having done all that and gotten ready to work on the turret as the next phase, I started looking at the reference photos again in order to determine what details I needed to adjust and how I was going to go about them. It was then that I realized something that I hadn't before...#421 has the side schurzen for the hull mounted in reverse from what the DML and Eduard instructions called for. The angled bend in the rails is mounted at the rear and not the front as called for and which I dutifully followed in the PE and kit instructions. This sparked my curiosity so I went back and looked at multiple III-Ms with schurzen to see if DML and Eduard had gotten this wrong somehow. What I found is that the schurzen were often mounted either way...which makes sense I guess when you realize that these were field-installed kits and not factory installed so some variation would be possible and the photo references bear this out.

While that gave me some peace of mind that I was in fact not going crazy or seeing things...it did mean that I needed to remove the rails from both sides and swap them around to get the right arrangement as that featured on #421. This was accomplished by carefully removing the rails from the support arms and then re-gluing them to the correct side. Getting them to realign properly was a lot trickier doing it this way since I'd lost my frame of reference originally used on the first installation, so once one side was in place the other had to be carefully lined up with it using visual points of reference on the vehicle itself.

The schurzen were then test fitted on both sides to make sure I had the right height alignment as well as horizontal alignment. Everything looked good so it was on to the turret after a couple of hours of reworking some of the previous stuff.

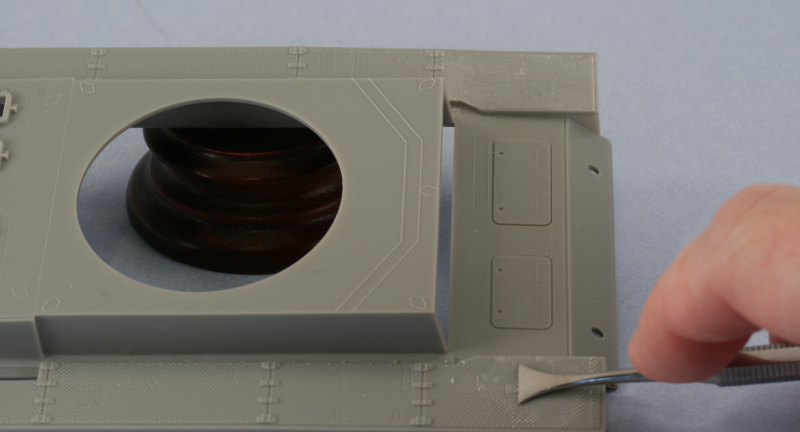

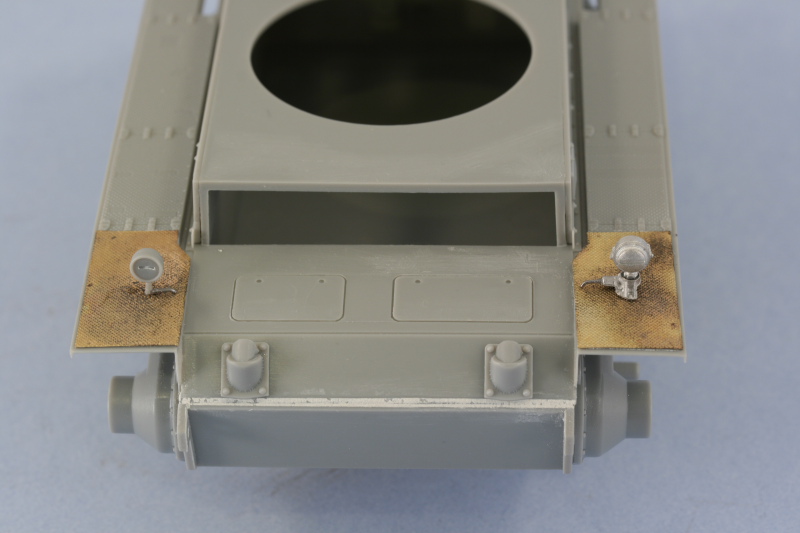

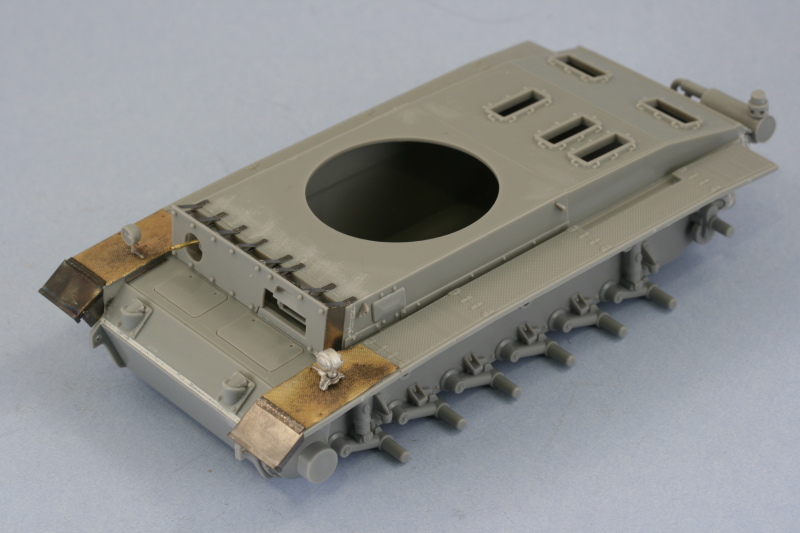

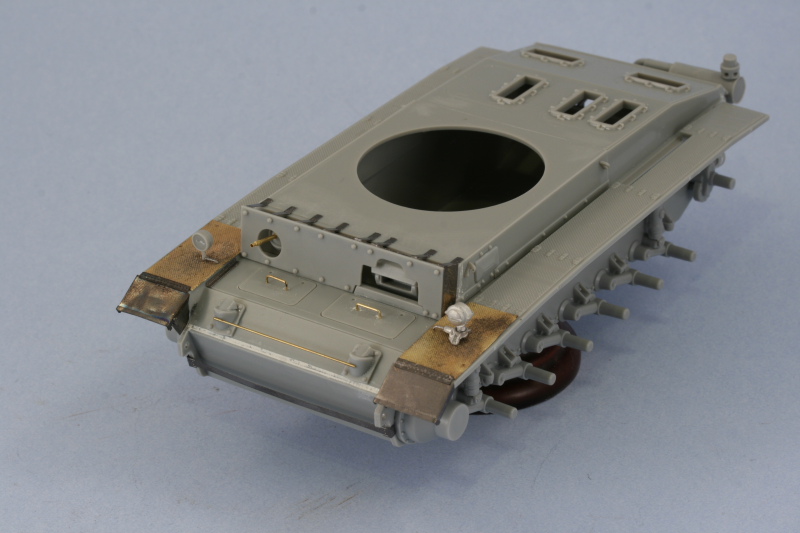

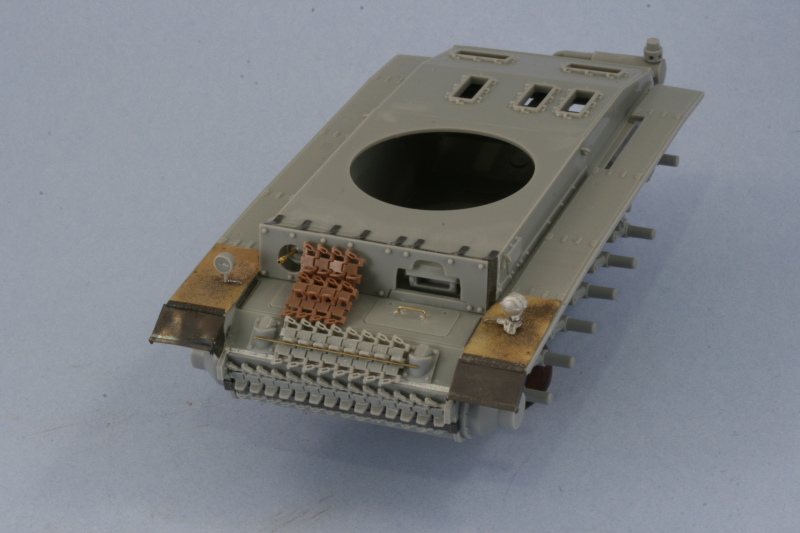

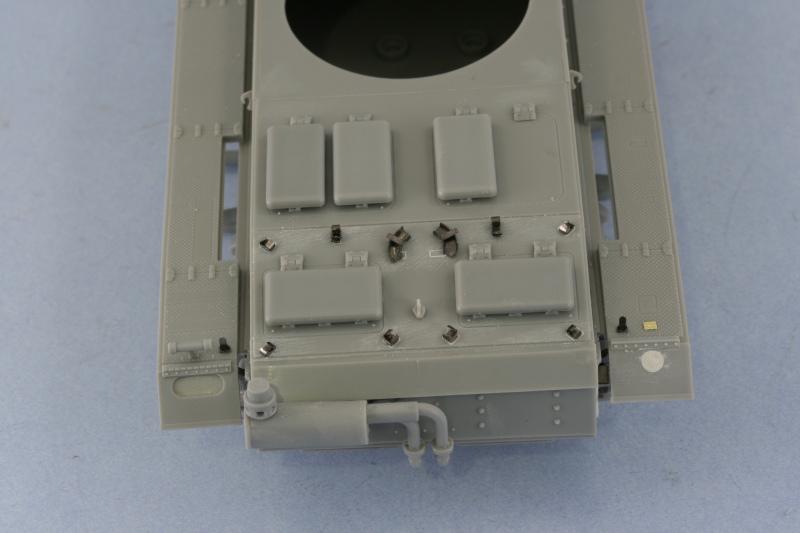

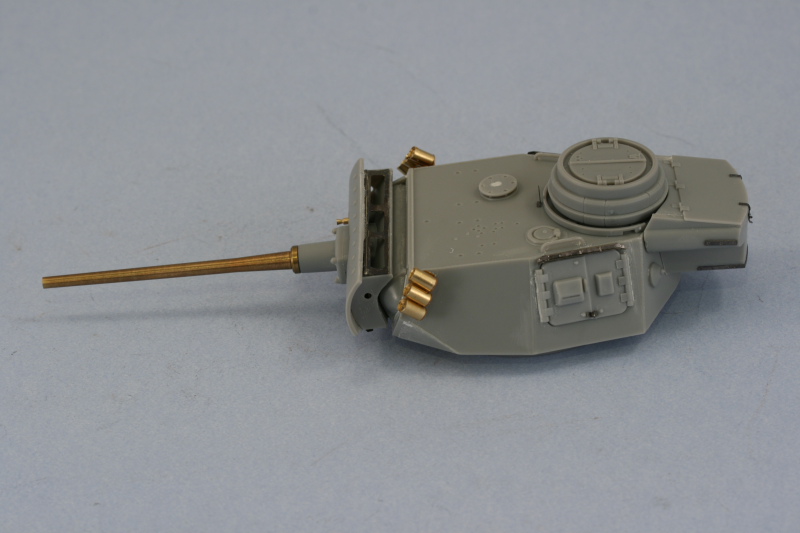

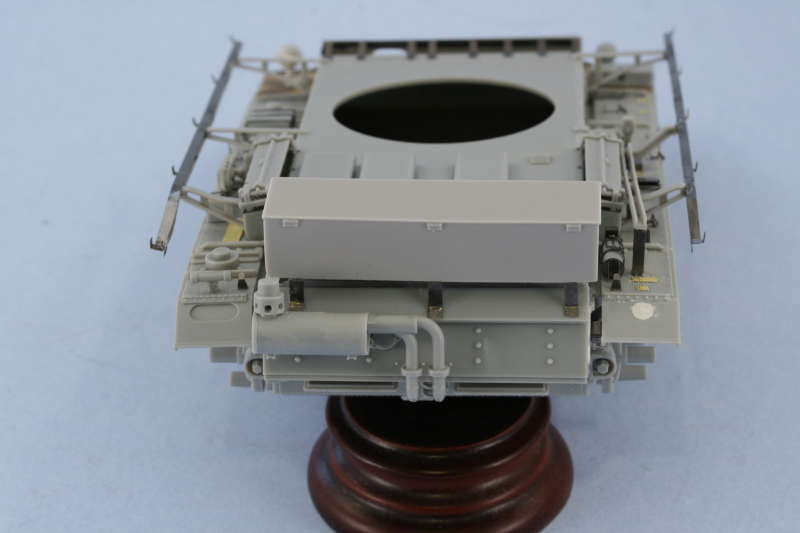

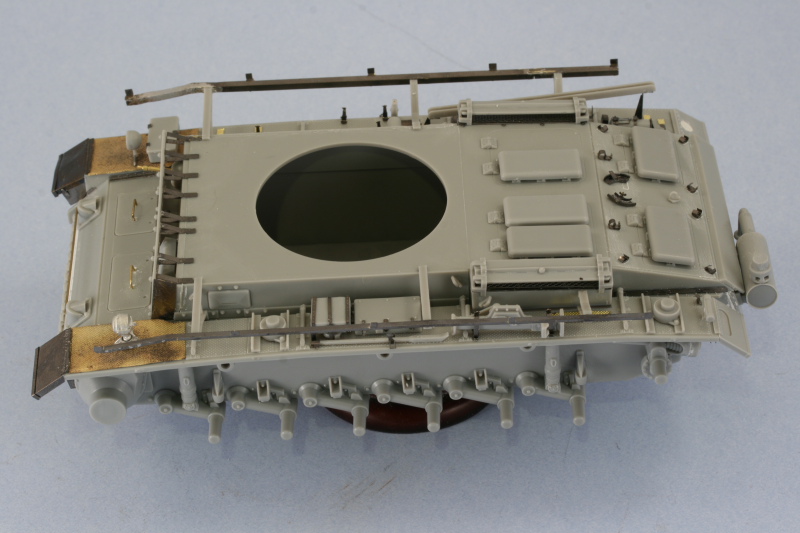

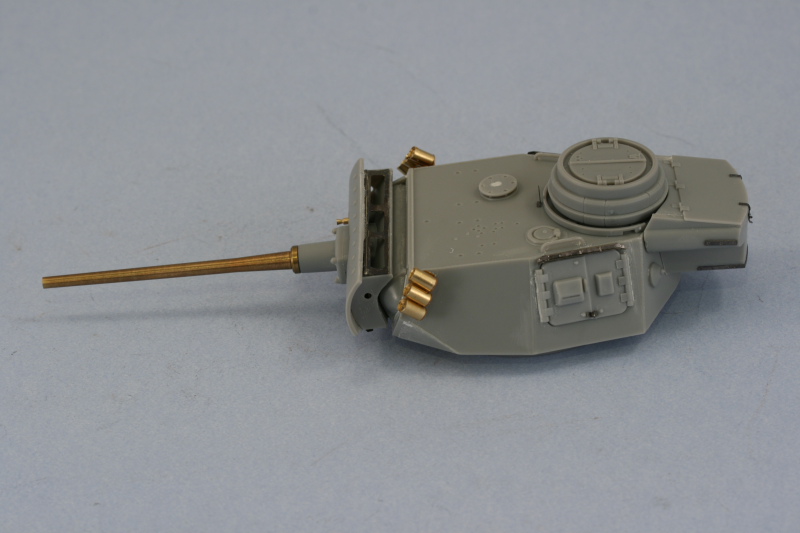

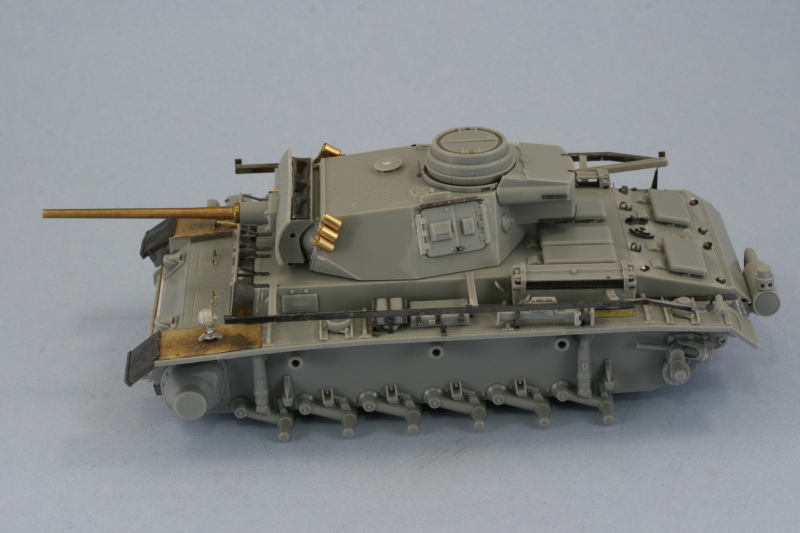

Work on the turret begins in Step 16 and this calls for the joining of the upper turret half with the lower and the installation of the internal portion of the mantlet and gun mount. The two turret halves generally fit together ok but there was some slight damage to the triangular cheek pieces that required some careful gluing and putty work to correct. The two-piece gun mount was assembled and the seam carefully sanded down since it's partially visible even with the external mantlet fitted and the pivot mounts installed allowing the mantlet to still elevate freely. The pivot mounts needed some putty work to fill a slight gap on both sides.

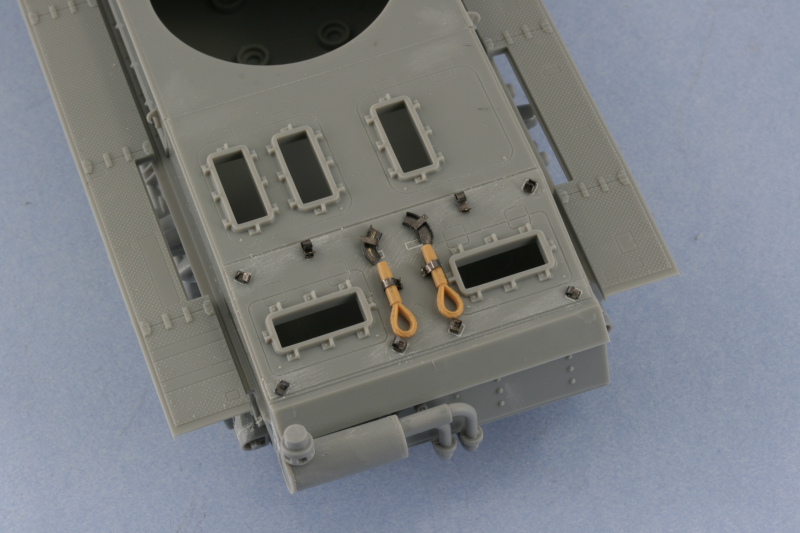

Step 17 assembles and installs the commander's cupola. This went together without any issues and installed the hatches in the closed position. The splash guard ring had it's molded on sight pointer removed and the Eduard PE item installed in its place. The armored ventilator cover had a mold sink mark in the center that was filled with putty and carefully sanded down before it was glued into position.

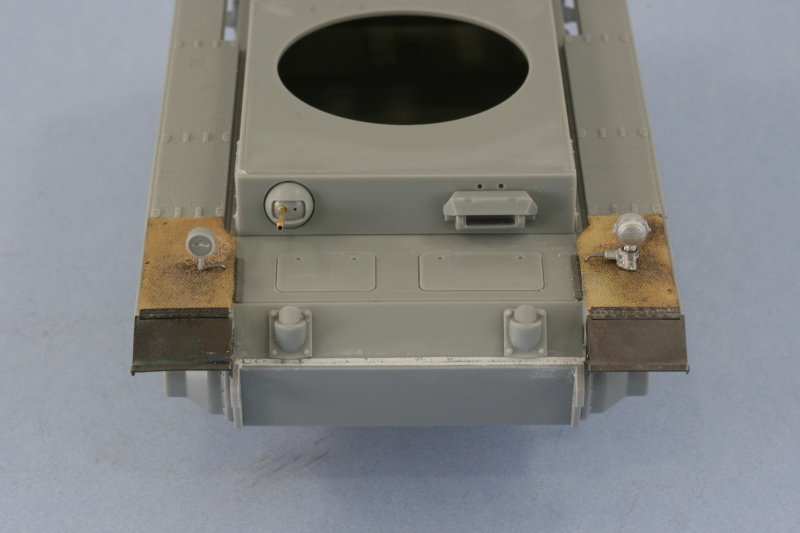

Step 18 adds more details to the turret in the form of the smoke launchers, side hatches, grab handles, and the rain gutters. I replaced the kit parts completely with the Voyager PE and turned brass set and left the lower two launchers empty on the right hand side in keeping with what shows in the photos. The Voyager PE parts for the lifting hook were insanely tiny to work with so I used the Eduard PE lifting hooks instead.

The one-piece side hatch doors were glued into place and their locking points removed and replaced with the Eduard items. Some putty was required to close up slight gaps on either side of each hatch set and the rain gutters were completely replaced with the Eduard PE items. The kit-supplied grab handles were added to the turret roof but the holes provided are too large of a diameter, so once the handles had set more putty was used to fill the remaining holes to round out this step.

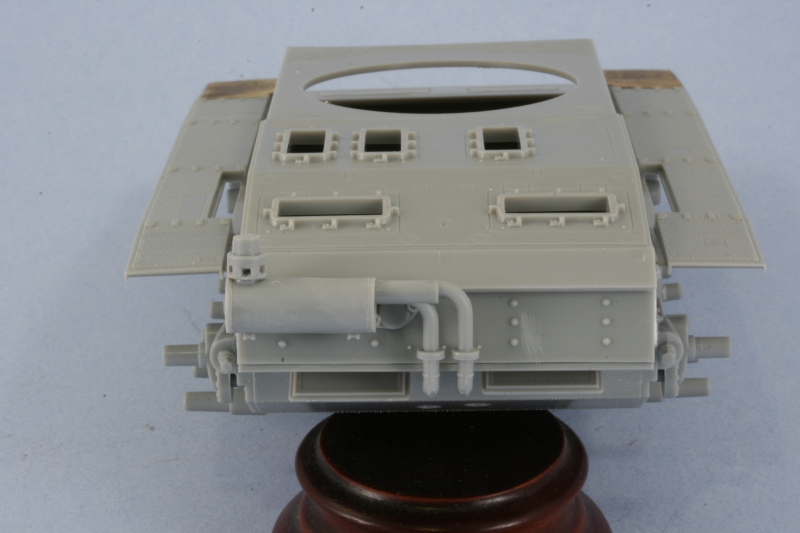

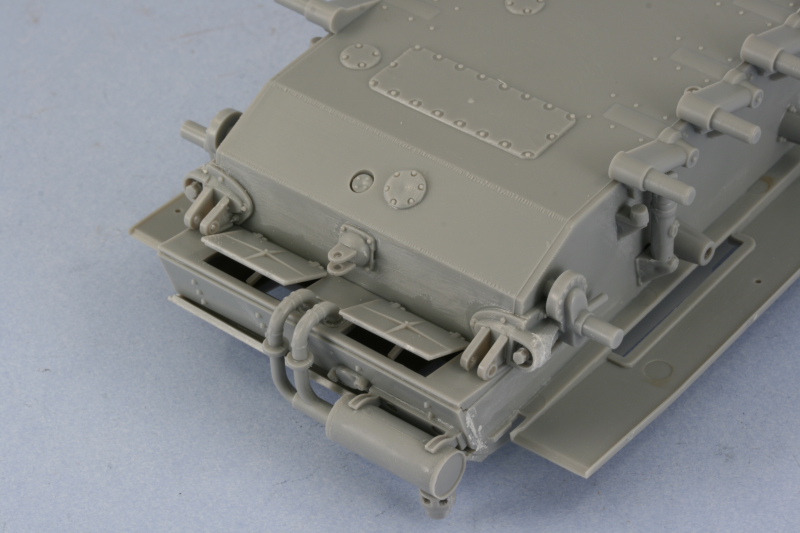

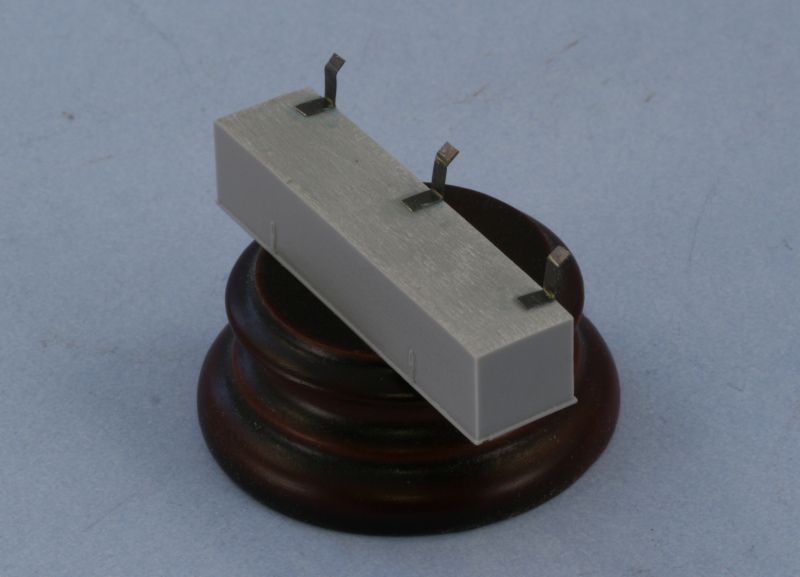

Step 19 adds the rear turret bin and the pistol ports to the turret. The bin is two-piece and went together fairly easily with just a little bit of putty required at one corner. The molded on latch tabs were removed with a #11 blade and the Eduard items added in their place and the absent wood rubbing strips added to the bottom and sides also courtesy of the Eduard set. The bin was then carefully installed to the turret rear taking care to make sure it was lined up square since that will be important when the turret schurzen are fitted.

Step 20 deals with the construction of the external mantlet and main gun and installation into the turret. I assembled the two-part recoil housing and once the glue had set carefully sanded down its seam and then glued it into position on the mantlet. The gunner's armored port was added as well and the coaxial MG installed using the turned brass barrel from the Armorscale damaged set mentioned in my first few posts. The kit barrel was replaced in its entirety using the Model Point turned brass barrel and locking ring which were installed using CA gel to insure a solid tight join. The end of the barrel recoil housing had two very prominent ejector marks which had to be filled with putty and carefully sanded down in order to eliminate them.

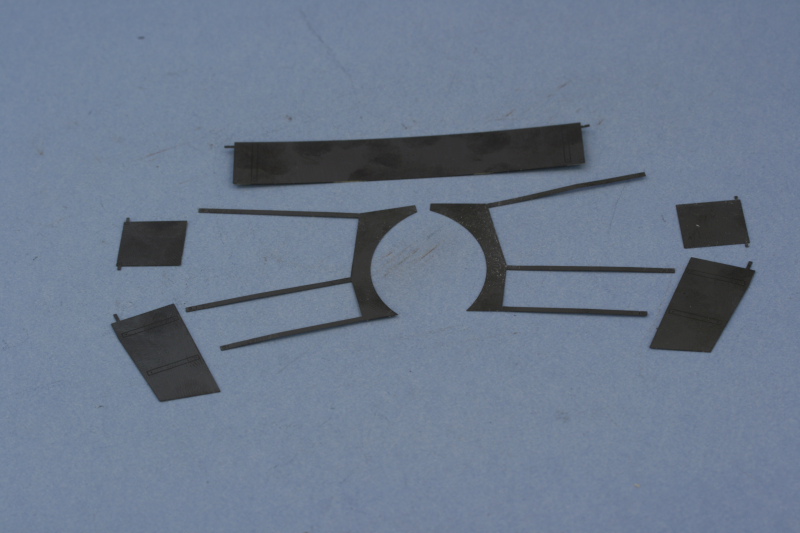

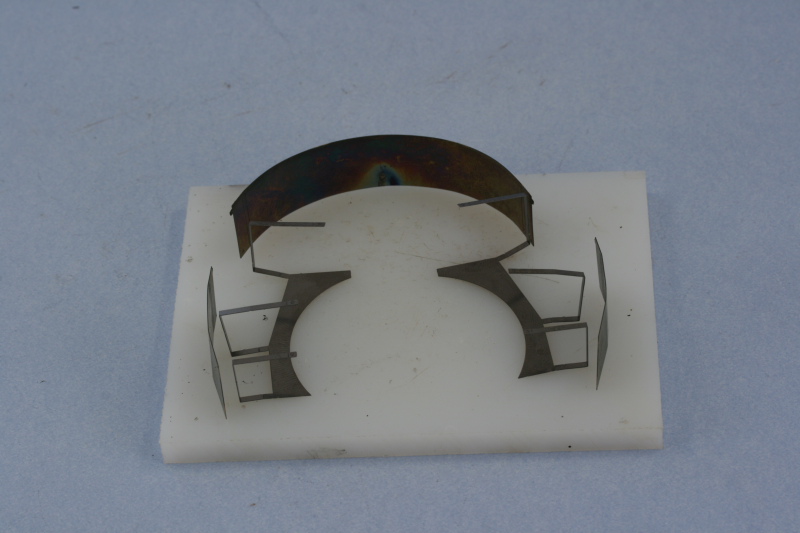

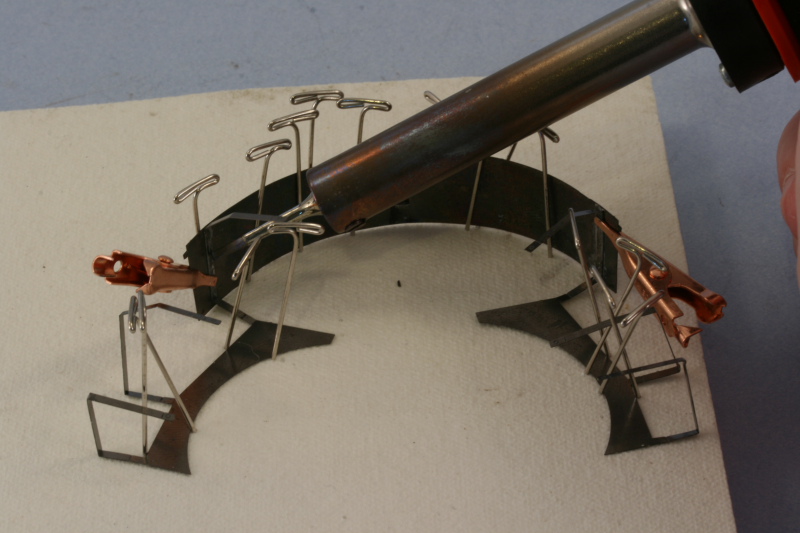

Next came the moment of truth...the construction and attachment of the Vorpanzer plates and spacers and then installation into the turret. To accomplish this, I opted for a hybrid approach using the PE from the CMK set for the top and bottom braces while staying with the kit-supplied styrene parts for the curved side plates for better strength and adhesion to the styrene external mantlet. Once the Vorpanzer was assembled and set, the mantlet was then glued into the turret. Since the inner portion of the mount could still elevate, the weight of the barrel pulled it all the way down.

To deal with that, I carefully applied some liquid glue on the inside of the mounts and then positioned the gun barrel in the desired elevation. It was then allowed to set up for an hour while in position on the hull to be sure it was where I wanted it to be.

The last thing to deal with before paint is the turret schurzen, so that will be goal #1 for tomorrow!